Connected Compactor

Seamlessly integrated technology that simplifies the management of commercial compactors.

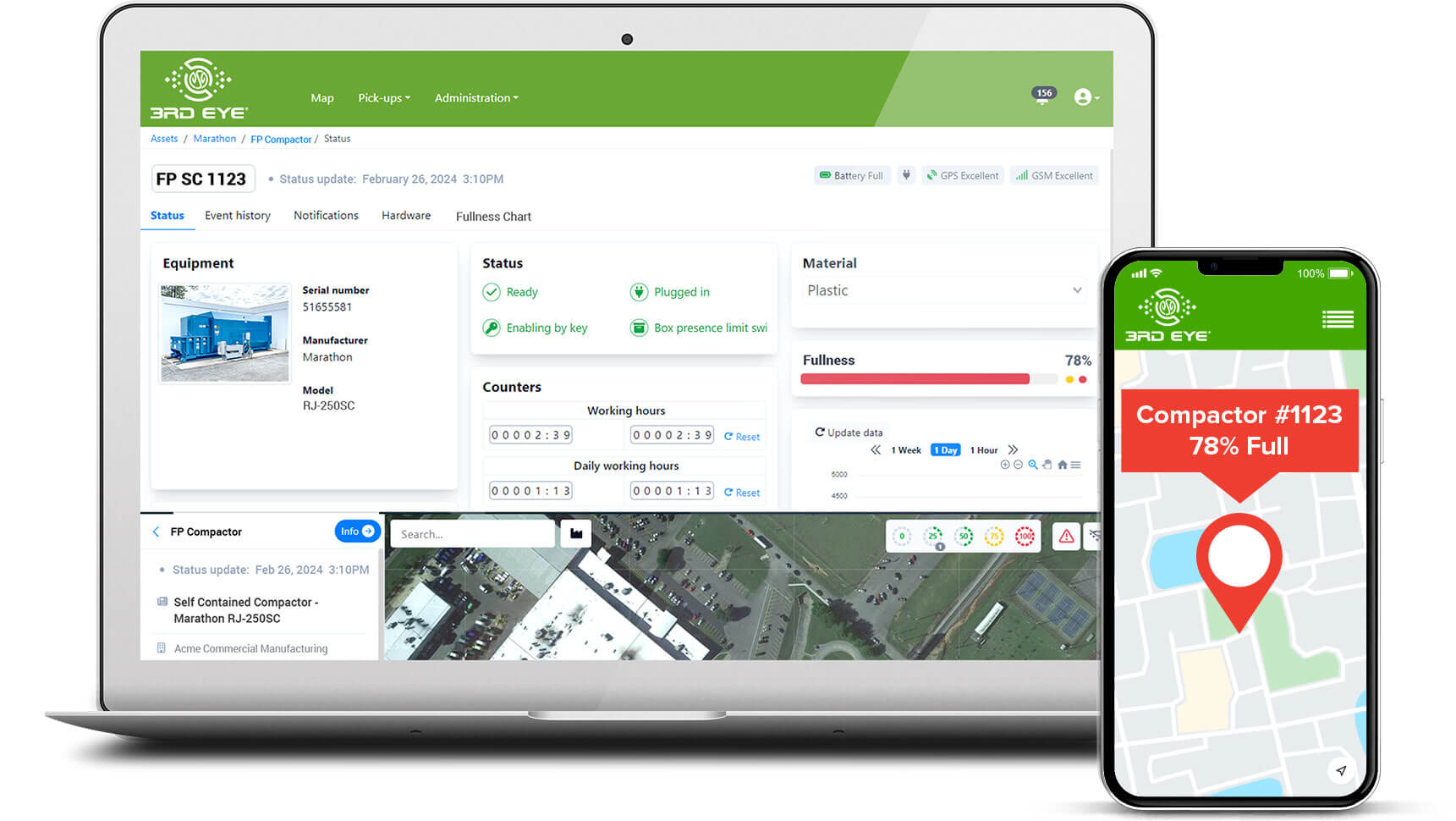

Complete compactor information, right at your fingertips.

3rd Eye Digital’s Connected Compactor products provide a comprehensive suite of technology solutions that seamlessly connect you to your compaction equipment. This integration provides unparalleled insights that enable users to reduce costs, enhance efficiency, and profitability, while furthering sustainability objectives.

FULLNESS MONITORING

TRACKING & LOCATION

UTILIZATION METRICS

STATUS & WORKING CONDITION

REAL-TIME NOTIFICATIONS

PERSONALIZED REPORTS

The Compactor Challenges.

Managing compactors across multiple sites can be highly inefficient, putting you at a significant disadvantage. The lack of a unified system for monitoring compaction equipment forces you to visit each unit or depend on team updates. This manual approach introduces substantial variability in operations, as perceptions of when a compactor is full can vary significantly. These discrepancies can result in inconsistent waste management practices, leading to inefficiencies, higher costs, and unnecessary collection delays. Without a standardized method to measure fullness, managing compactors relies on subjective judgments rather than precise, data-driven insights.

Connected Compactor Revolutionizes The Management Of Compaction Equipment.

3rd Eye Connected Compactor transforms your compaction process by delivering comprehensive, real-time insights for proactive compactor management and optimization.

With Connected Compactor, you gain real-time monitoring of waste or recycling levels, enabling a proactive approach to waste collection based on actual fullness. This optimizes hauling frequency, reduces operational costs, and enhances sustainability. Additionally, real-time notifications and maintenance alerts keep you informed, minimizing downtime and ensuring your compactors remain operational and highly efficient.

Revolutionize your waste and recycling management operations with 3rd Eye’s Connected Compactor, turning your compaction process into a strategic asset for your operations.

Fullness Monitoring

Accurate fullness monitoring allows for precise service scheduling.

Tracking & Location

All crucial compactor information for each piece of compaction equipment is available right at your fingertips.

Utilization Metrics

Know exactly how your compactors are being utilized with actionable metrics in the user dashboard.

Status & Working Condition

See the status and working condition of every unit, monitor health to ensure maximum uptime.

Real-Time Notifications

Receive real-time notifications for compactor events, such as fullness, status, and working condition.

Personalized Reports

Customizable ad-hoc and recurring reports to help drive business decisions.

Precise Asset Tracking.

Optimize Pickup Service Scheduling.

Our robust layer of APIs allows for seamless integration of full compactor details into your back-office system. Alternatively, you can utilize our streamlined user interface to quickly and accurately gain complete insights into your compaction equipment. Real-time data enables precise asset control and maintenance planning, and optimization of hauler pickup through accurate fullness monitoring. Maximize your compactor efficiency, reduce costs, improve sustainability while boosting profitability.

Add immediate value to your compactor operations

- Sustainability

- Precise Asset Tracking

- Optimized Service Scheduling

- Improved Maintenance Planning

- Communicated Asset Utilization

- increased Recyclable Recovery

3rd Eye Connected Compactor.

You handle the front of the store, we’ve got the back.

To learn more about how 3rd Eye Connected Compactor can help optimize service scheduling, refine process flows, increase recyclable recovery, and improve maintenance planning, contact us today and request a no-obligation demo.

Convenient Monthly Ownership Options, Customized For Your Specific Needs.

The 3rd Eye monthly ownership options offer a convenient Hardware as a Service (HaaS) model that significantly reduces the upfront costs of equipment, aiding in the success of your business. Along with industry-leading camera systems, you’ll gain peace of mind through comprehensive technical service, support, and warranty protection. Our innovative approach to solution packaging is designed to enhance your total value stream while minimizing your initial out-of-pocket investment. For more information on our monthly ownership model and to learn more about the terms and conditions, please contact us to get started today.

3rd Eye Connected Compactor.

You handle the front of the store, we’ve got the back.

To learn more about how 3rd Eye Connected Compactor can help refine process flows, increase recyclable recovery, and increase commodity revenue, contact us today and request a free, no-obligation demo.